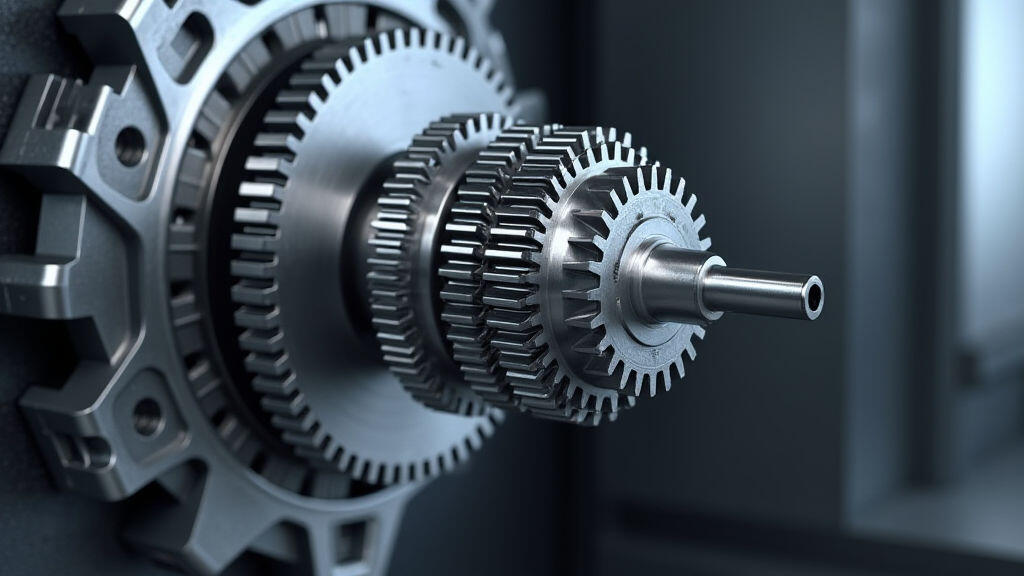

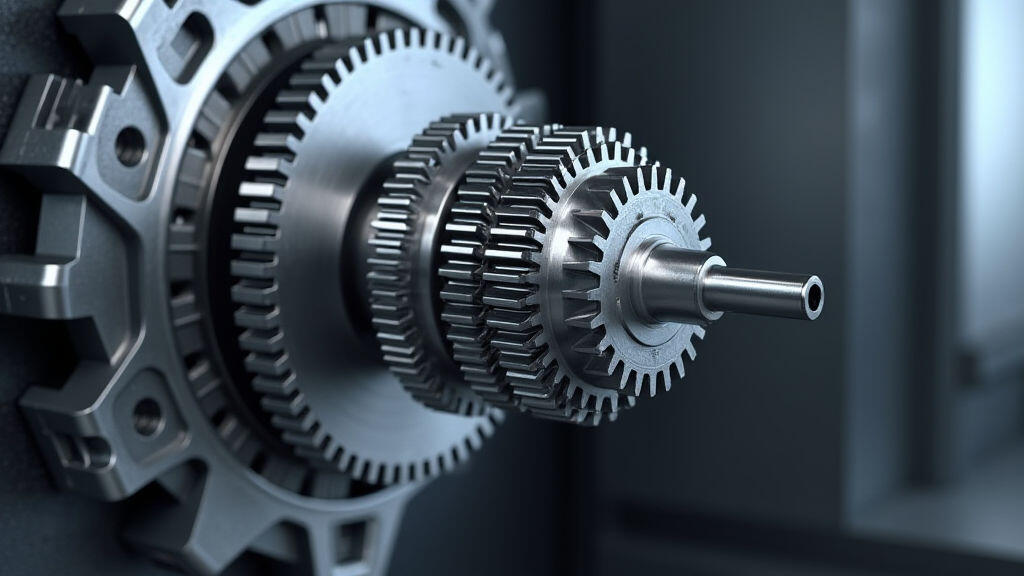

The CNC (Computer Numerical Control) machine tool industry is undergoing a rapid transformation, driven by advancements in automation, precision, and digitalization. At the heart of this evolution lies the humble, yet critical, gear motor – the unsung hero that translates electrical power into the precise rotational motion required for cutting, milling, drilling, and other manufacturing processes. Selecting the right gear motor isn’t simply about matching voltage and torque; it's about optimizing performance, minimizing downtime, and maximizing overall efficiency in a competitive landscape increasingly focused on Industry 4.0 principles and predictive maintenance. This article shares practical experience and insights into gear motor selection for CNC applications, highlighting current trends, challenges, and best practices.

Before diving into selection criteria, it's essential to understand the fundamental role gear motors play. In a typical CNC machine, gear motors are used for various functions:

The precise requirements for each application dictate the specifications of the gear motor. A spindle drive, for instance, demands significantly higher power and rotational speed compared to a feed drive.

Choosing the right gear motor involves a detailed consideration of several key factors:

1. Torque and Speed Requirements: This is the most obvious, but also the most crucial. Precise calculations are necessary to determine the required torque at the desired speed for the specific application. Factors to consider include the cutting forces, material being processed, and desired surface finish. Over-sizing can lead to inefficiency and increased cost, while under-sizing results in performance limitations and potential machine damage. A common mistake is focusing solely on peak torque and neglecting the continuous torque requirements which are critical for sustained operation.

2. Gearbox Type and Efficiency: The gearbox significantly impacts the gear motor's performance. Different types of gearboxes (planetary, helical, bevel-and-gear, worm) offer varying levels of efficiency, backlash, and noise. Planetary gearboxes are often preferred for high torque density and compact size. Efficiency is paramount, as it directly affects energy consumption and operating costs. Modern gearboxes can achieve efficiencies exceeding 95% under optimal conditions.

3. Accuracy and Precision: CNC machines are renowned for their high precision. Consequently, the gear motor's accuracy and precision are equally important. Factors like backlash and dynamic accuracy must be carefully considered, especially in high-precision applications. Backlash, the amount of play in the gears, can introduce errors in positioning and affect the quality of the finished product.

4. Cooling Requirements: CNC machines often operate continuously, generating significant heat. Adequate cooling is crucial to prevent overheating and maintain optimal performance and lifespan of the gear motor. Cooling methods include forced air cooling, liquid cooling, and oil immersion. The choice of cooling method depends on the power rating of the motor and the ambient temperature.

5. Environmental Considerations: CNC machine tools operate in diverse environments, ranging from cleanrooms to harsh industrial settings. The gear motor must be designed to withstand the specific environmental conditions, including dust, humidity, vibration, and temperature fluctuations. IP (Ingress Protection) ratings are crucial for assessing the motor’s protection against environmental hazards. For example, in food processing CNC applications, food-grade seals and materials are mandatory.

6. Noise and Vibration: Excessive noise and vibration can be a significant problem in CNC machine tool environments, impacting worker comfort and potentially affecting machine accuracy. Design features like optimized gear geometry and vibration damping materials can help minimize noise and vibration levels.

Several emerging trends are influencing gear motor selection in the CNC machine tool field:

1. Direct Drive Systems: Direct drive systems, eliminating the gearbox altogether, are gaining traction, especially in applications requiring high precision and responsiveness. These systems typically use high-torque, low-speed servo motors directly coupled to the spindle. They offer advantages like reduced backlash, improved efficiency, and simplified maintenance. However, direct drive systems can be more expensive and require sophisticated control algorithms.

2. Integrated Motor-Gearbox Solutions: Manufacturers are increasingly offering integrated motor-gearbox solutions – pre-engineered combinations optimized for specific CNC applications. These solutions simplify the design process, reduce lead times, and ensure optimal performance. MES-Drive, for example, offers a range of integrated solutions tailored to various CNC machine tool requirements.

3. IoT and Predictive Maintenance: The rise of Industry 4.0 is driving the adoption of Internet of Things (IoT) technologies in CNC machines. Sensors integrated into gear motors can monitor parameters like temperature, vibration, and current draw, providing valuable data for predictive maintenance. This allows for identifying potential problems before they lead to machine downtime, reducing maintenance costs and improving overall productivity.

4. Energy Efficiency Focus: With increasing energy costs and a growing emphasis on sustainability, energy-efficient gear motors are becoming increasingly important. Advanced motor designs, optimized gear geometries, and energy recovery systems can help reduce energy consumption and lower operating costs.

MES-Drive is dedicated to providing high-quality, reliable gear motor solutions for the CNC machine tool industry. Our comprehensive range of gear motors, coupled with our engineering expertise, enables us to offer customized solutions tailored to specific application requirements. We understand the importance of energy efficiency, precision, and durability in CNC machines and continuously strive to innovate our products and services to meet the evolving needs of our customers. Our team works closely with CNC machine builders to provide technical support and guidance throughout the gear motor selection process, ensuring optimal performance and long-term reliability. We also offer predictive maintenance services based on data collected from our IoT-enabled gear motors, helping our customers minimize downtime and maximize productivity.

Gear motor selection is far from a simple task in the context of modern CNC machine tools. It demands a comprehensive understanding of application requirements, technological advancements, and emerging trends. The adoption of direct drive systems, integrated solutions, IoT-enabled predictive maintenance, and a strong focus on energy efficiency are reshaping the landscape of gear motor technology. These advancements are paving the way for more precise, efficient, and sustainable CNC manufacturing processes.

As industries continue to embrace Industry 4.0 principles and the demand for higher precision manufacturing intensifies, the role of gear motors will only become more critical. MES-Drive is committed to being at the forefront of this evolution, providing innovative solutions and expert support to help our customers achieve their manufacturing goals. The convergence of advanced gear motor technologies and data-driven insights represents a significant opportunity for CNC machine tools to enhance performance, reduce costs, and maintain a competitive edge in the global marketplace – and MES-Drive is proud to be a part of that journey.

Leave A Reply

Your email address will not be published. Required fiels are marked